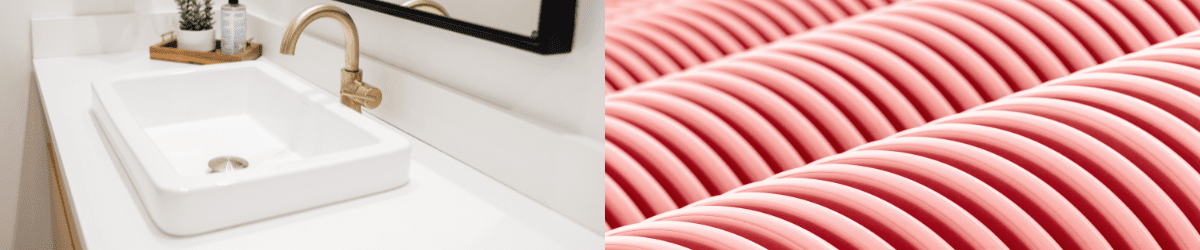

Sanitary and Heating Pipes

Extreme temperature resistance without crosslinking:

PERT Type II

Our innovative high density polyethylene pressure pipe grade XRT70 combines excellent processability with elevated temperature performance and long-term stability to raise performance to a level highly recognized by the industry. Typical applications include hot & cold water domestic plumbing, underfloor heating, radiator connections, infrastructure surface heating, cooling and deicing as well as industrial applications e.g. in corrosive environments.

Built for efficiency & durability

Speed and consistency:

XRT70’s bimodal design offers outstanding processing properties. High extrusion speeds can be reached at low temperatures and without any melt fracture, while keeping an excellent surface finish for all pipe dimensions and structures (low sag for large diameter and excellent gauge for multi-layer pipes).

Long life span:

XRT70 offers the longest service life in actual operation thanks to its thermal stability and stress crack resistance.

It is more than compliant to standards:

• PERT Type II (ISO 24033)

• Suitable for application classes 1,2,4,5

(ISO 10508)

• Classified MRS 10 MPa (ISO 9080)

PP Heavy Duty Grades for Sewage and Drainage

A part solution to water management challenges

Plastic piping solutions enable up to 10-fold reduction of pipe weight over traditional materials like concrete. TotalEnergies’ latest PP generation provides even further reduction of pipe weight without compromising on durability and impact properties. Among the many benefits our grades have to offer you will find flexibility, durability, a broad temperature window and high abrasion resistance.

The typical applications for these grades range from indoor waste and soil discharge to underground sewage and drainage (smooth or corrugated/structure wall).

Improving the sustainability of gravity pipes

Reducing the environmental footprint of our activities, products and services is part of TotalEnergies’ strategy. The very high stiffness of PPC 1645 allows the production of sewage & drainage pipes at minimum wall thickness, in accordance with existing standards. In combination with the inherently low density of polypropylene, PPC 1645 provides a significant pipe weight and greenhouse gas emission reduction compared to industry standards.

PPC 1645 for full wall sewage pipes

Pipes made with PPC 1645 exceed all requirements for high stiffness pipes at lowest wall thickness permitted by European norms. Impact resistance is at the highest level to warrant trouble-free installation in subzero conditions. The tailored additivation package warrants long term performance under nearly all operating conditions.

PPH 1060 for mineral modified pipes

PPH 1060 is a polypropylene homopolymer that has been specifically developed for the production of mineral modified pipes used in sewage and drainage applications. Thanks to its tailor-made molecular weight distribution, PPH 1060 can absorb much more mineral filler even up to 50 wt%. PPH 1060 also exhibits high crystallinity for superior thermal and chemical resistance and comes with an adapted stabilization package to provide high temperature resistance and long service life.